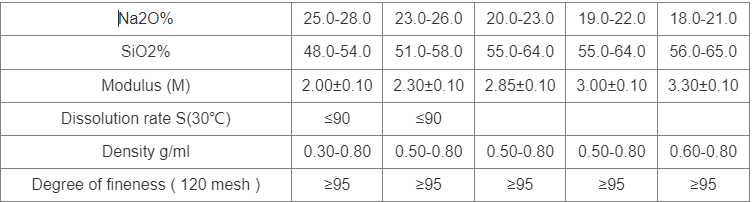

Technical Parameters of Powdered Immediate Sodium Silicate (CAS 1344-09-8)

(Technical Parameters of Powdered Instant Sodium Silicate (CAS 1344-09-8))

Keep in mind: We can also personalize salt silicate powder with moduli of 2.45, 2.5, and 3.4 according to your needs.

Our Variety Of Sodium Silicate Moduli

We offer powdered split second sodium silicate with moduli varying from 2.0 to 3.3. Furthermore, we can personalize salt silicate powder with moduli of 2.45, 2.5, and 3.4 to fulfill your specific demands.

Introduction

In an era where ecological sustainability and protection are increasingly prioritized, salt silicate, additionally referred to as water glass or soluble glass, has become a topic of considerable rate of interest throughout numerous industries. This versatile inorganic compound is vital in construction, paper production, and the solution of detergents. The gradual phase-out of traditional phosphorus-based detergent ingredients, such as salt tripolyphosphate (STPP), because of their harmful influence on water atmospheres, has actually developed a pressing need for efficient and environment-friendly options. Salt silicate, with its special buildings, has actually emerged as a feasible and eye-catching alternative.

Market Potential

2.1 Worldwide Demand Patterns

The global market for focused artificial cleaning agents is experiencing steady development, specifically with the enhancing popularity of ultra-concentrated powders. In 2000 alone, it was estimated that at the very least 230,000 lots of salt silicate were required to satisfy the need. Given the present limited worldwide supply, there is a remarkable gap between supply and demand, indicating considerable growth possibility. As customers progressively look for top quality and environmentally friendly items, the market for salt silicate is anticipated to expand substantially.

2.2 International Competitive Position

Chinese-produced salt silicate usually supplies a much more affordable rate and equivalent, if not exceptional, high quality contrasted to similar items manufactured globally. For instance, the FOB rate of salt silicate in the United States is around $51.15 per 100 extra pounds, while costs in Europe are even greater. This cost advantage positions Chinese producers positively in the global market. By constantly introducing and boosting item quality, Chinese producers have the possibility to catch a larger share of the global market.

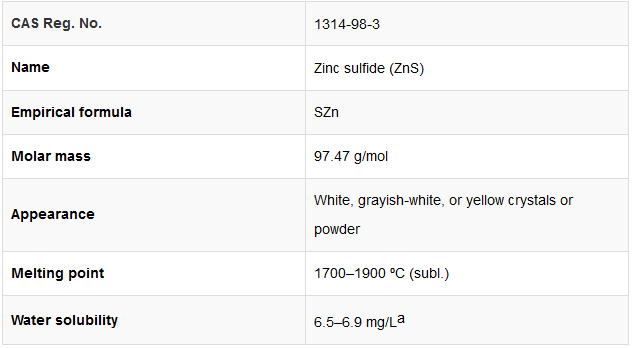

Overview of Salt Silicate

Sodium silicate is a compound composed of silicon dioxide (SiO โ) and salt oxide (Na โ O), commonly represented by the formula Na โ O ยท nSiO โ, where n varies depending upon the details type. It is known for its good solubility, high pH level, and excellent cleansing residential or commercial properties, making it a suitable additive for detergents. Past its use in cleaning agents, salt silicate is extensively used in the construction sector, such as in waterproofing products and sealers. In the paper sector, it improves the stamina and level of smoothness of paper. In addition, it finds applications in textile dyeing, oil removal, and other markets.

Production Refine

1. Preparation of Raw Products: The procedure starts with the option of suitable resources, consisting of silica sand or soluble glass, in addition to caustic soda.

2. Dissolution Phase: The raw products are combined and heated to a proper temperature to help with dissolution, making sure extensive mixing of all parts.

3. Formation Control: Details problems are controlled to advertise the development of desired crystal structures in the option. Temperature level and pressure specifications need to be specifically managed during this phase.

4. Purification and Filtration: A plate and structure filter press is utilized to get rid of excess moisture and pollutants, therefore guaranteeing the final product’s pureness.

5. Drying out and Developing: Spray drying out modern technology is utilized to decrease the wetness content even more, causing a powder form that is easy to store and transport.

Financial Analysis

From a monetary perspective, the production of sodium silicate presents clear advantages. For a plant with a yearly ability of 5,000 loads, the price break down is as complies with:

1. Variable Costs: Approximately $346.71 per heap, that includes basic materials (silica sand/soluble glass and caustic soda), energy consumption (electrical power and fuel), and labor costs.

2. Fixed Costs: Around $141,400 each year, covering devaluation of fixed possessions, upkeep, management charges, loan passion, and other costs.

3. Complete Expenses: The combined total price is approximated at $385.71 per heap.

4. Sales Profits: With an estimated asking price of 642.86 perton, theprofitmarginpertonwouldbeapproximately642.86 perton, theprofitmarginpertonwouldbeapproximately257.15.

5. Economic Perks: The project can create yearly earnings of around 3.21 million, contributingroughly3.21 million, contributingroughly1.29 million in tax income.

This financial evaluation indicates that sodium silicate not just supplies significant technological advantages yet is additionally very economically practical. For producing firms, investing in the manufacturing and promo of sodium silicate can generate substantial economic returns while enhancing their business social duty picture.

( sodium silicate)

Verdict

In summary, salt silicate, with its premium technological efficiency and reduced manufacturing expenses, holds excellent possible as a replacement for conventional phosphorus-based ingredients. As ecological regulations end up being stricter and customer need for premium, eco-friendly items expands, increasing the study, growth, and commercialization of sodium silicate will certainly be important for transforming the international detergent sector. For financiers, entering this area not just supports company social duty but also guarantees eye-catching financial returns and social advantages. With ongoing technical innovations and a broadening market, the potential uses salt silicate are comprehensive and merit additional exploration and advancement by industry stakeholders and research institutions.

Top notch Sodium Silicate provider

TRUNNANO is a supplier of Sodium Silicate Materials with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about liquid silicate, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us